There are large and small bus shelters. The length of the small shelter is several meters, while the length of the large shelter can reach more than ten meters. For small bus shelters, integrated processing can be used, that is to say, during the production process of the bus shelter, according to the production process, the production of the bus shelter is completed at one time. On a pre-buried basis. This method greatly reduces the amount of on-site construction, saves costs, and facilitates transportation. However, for large bus shelters, considering the limitations of transportation, accessories need to be produced separately and assembled on site.

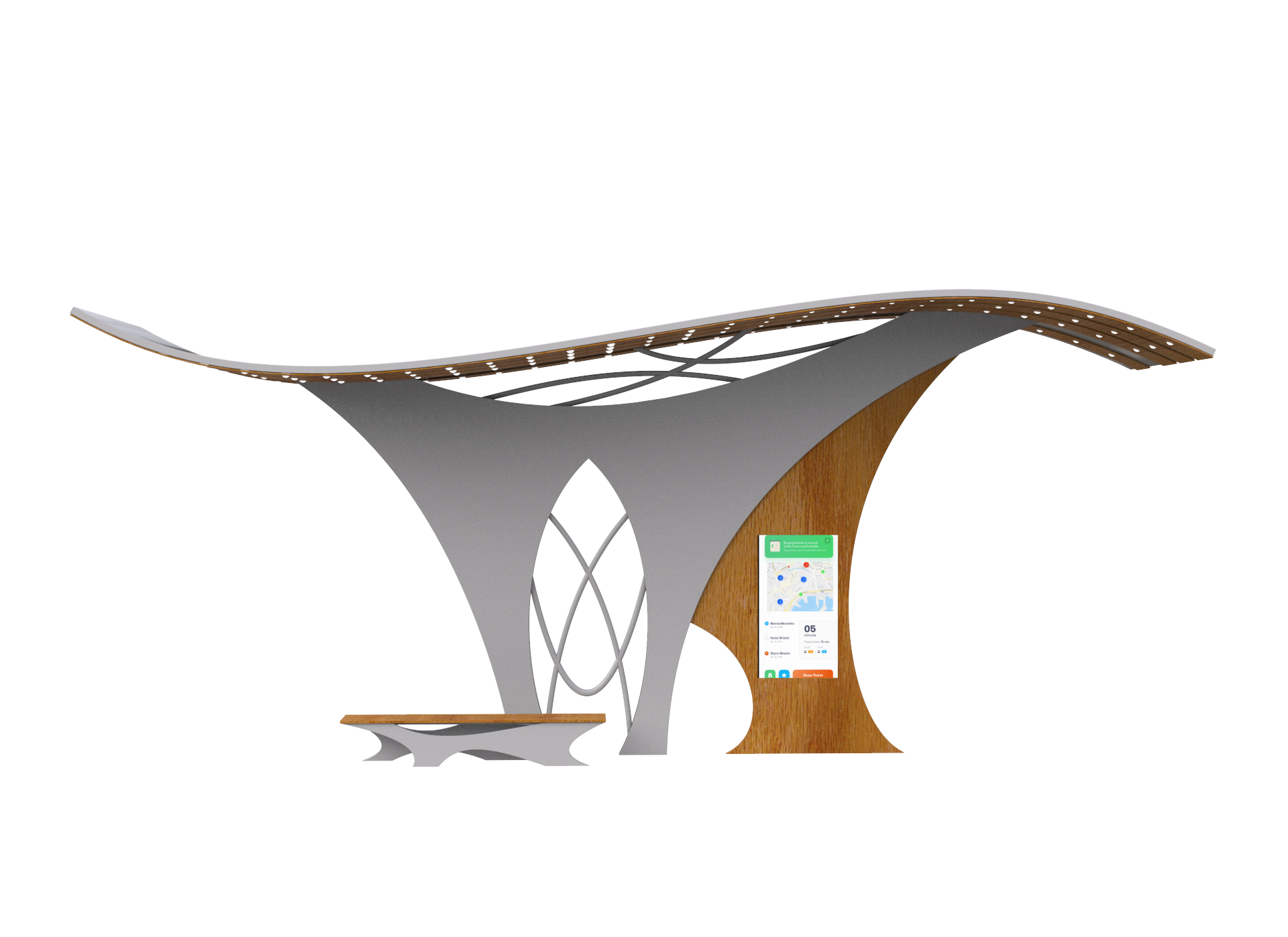

In the production of the bus shelter, the assembled bus shelter can generally be divided into several components: the ceiling, the column, the top bow, the advertising light box and the seat. The biggest advantage of the assembled bus shelter is that it becomes large and small, and it is convenient to transport.

The assembly steps of the bus shelter: the components are assembled in several parts: first install the column and the top bow to complete the main structure part; after the main part is assembled, the overall box assembly is carried out.

Shelter assembly requirements:

The parts should be placed on a simple fixture or an assembly table for assembly; during assembly, the overall dimensions, installation dimensions and key dimensions should be measured against the drawings at any time; when the parts in the light box have been assembled in place and adjusted to the specified size , you can tighten the fastening screws one by one. All fastener screws should have anti-loosening measures, and the nuts should be 3~5 buckles higher than the bolts after tightening.

Assembly requirements for the door of the shelter box:

a) After the door is installed, it should rotate flexibly and without deformation, and the opening angle of the door should not be less than 90°;

b) The function of the lock is smooth, and the style of the lock conforms to the requirements of the drawing;

c) Doors equipped with sealing moldings should not easily fall off when the opening and closing functions are vibrated, and the door should not automatically pop open after the door lock is opened;

d) The allowable deviation of the uniformity of the gap between the door and other structural elements shall not exceed the relevant ones.

After the bus shelter is installed, the overall dimensions are required:

a) See the standard for general tolerances for the height, depth, width and verticality of the outer dimensions of the shell;

b) Measurement method. The height measures the four corners; the depth measures the left and right sides, the upper, middle and lower three places; the width measures the front and rear sides, the upper, middle and lower three places. The deviation size is calculated according to the maximum of each part;

c) The general tolerance of the flatness of panel components such as side panels and doors is less than 3mm for any square meter. The panel is generally less than 1.5mm in any square meter.

During the assembly process of the bus shelter, the main structure of the bus shelter needs to be lifted by a crane. The lifting ring is the load-bearing part of the entire product. The lifting ring should be selected in strict accordance with the requirements of the drawing, and should not be replaced arbitrarily. After installation, all screws must be tightened.

After the installation of the shelter is completed, the installation holes and splicing plates need to be processed. The positions of the installation holes and splicing plates at the bottom of the shelter should meet the requirements of the drawings.

Inspection after the construction of the bus shelter on site: After assembly, the manufacturer of the shelter should conduct self-inspection according to the drawings and process regulations, and then submit it to a full-time inspector for inspection after passing the inspection.

Share to:

Share to: